The Environmental Health Story of

Sustainable Materials |

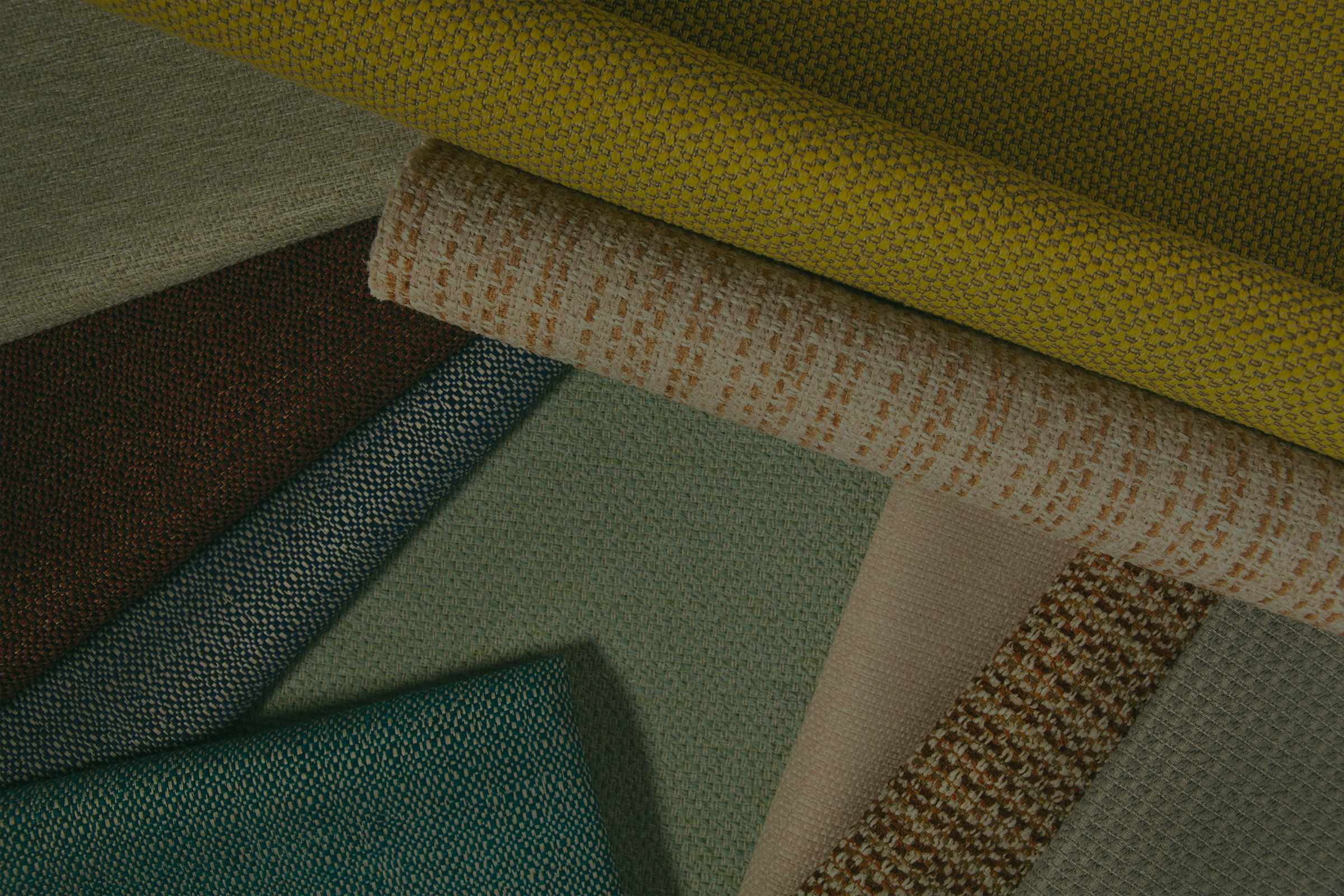

Many textiles of excellent value, performance and aesthetic are manufactured using rapidly renewable, organic, recycled, or biobased content. |

Built in performance |

High performance fabrics have cleanability, durability, and/or UV resistance built into their molecular structure rather than requiring any additives or finishes. |

Third Party Certification |

Textile sustainability claims verified by rating systems external to the vendor ensure detailed, professional evaluations of the material and its life cycle and are rated well by MSAP. |

Circularity |

Several vendors have invested in take back programs or improved reuse/disposal options to reduce the amount of textiles heading to landfills. |

Topical chemistry |

Textile performance can be improved by adding a finish, but not all options are sustainable. Avoid Teflon, PFAs, and undesirable chemicals that are red listed by Cal Prop 65. |

Phthalates, Formaldehyde, & Heavy Metals |

These chemistries should be avoided and may be present in old vinyl upholstery. New products utilize healthier alternatives to soften, cure, or stabilize the textile. |

Water usage |

Conventional techniques for growing crops and for dying natural & synthetic fibers are notorious wastes of water. New farming practices and dye techniques can reduce the amount of water formerly used up in textile manufacturing. |

Social Equity |

Look for third party social responsibility audits and participation in recognized Fair Labor & Human Rights programs such as Goodweave for assurance of adherence to human and social equity. |

Fiber producer Hyosung has introduced a completely recycled denim elastane fiber from reclaimed waste.The new fiber technology allows denim manufacturers the possibility of creating their product using 100% recycled material without the use of stretch polyester. Denim producers are excited to work with the eco-friendly denim elastane. Hyosungs other products, recycled UV cool-touch nylon and recycled UV cool-touch polyester, as well as recycled lightweight performance polyester were introduced at the February 2021 Kingspin24 Flash virtual event, along with the new denim elastane.

Read More

Hemp has been in use for centuries and only lost favor in the 20th century due to the ban of a similar Cannabis plant. Since 2018, hemp has been legal and growing strong. New long fiber varients are being developed for use in non-wovens, wovens and knits. Hemp does not require the water, fertilizers or pesticides common with cotton and helps promote healthy soil in rotation. Hemp fiber is more durable than cotton, has better UV properties than all other natural fibers, is hypoallergenic and antimicrobial. In combination with other fibers, hemp enhances strength and elongation, and reduces cost. Look for hemp to soon be entering into interior products.

Read More

Sustainability has hit the mainstream, with better options now expected by consumers. There are a number of innovative fabric suppliers, providing solutions without toxic additives. Kvadrat has recycled options made from wool or from polyester. Knoll and Pollack, along with many other vendors are providing recycled polyester styles. Maharam joins in with bio-based fabrics, while bio-based styles are also numerous from Carnegie. HBF offers rapidly renewable fabrics and the newest to join in, Sunbrella with recycled acrylic yarns sourced from manufacturing waste. With any of these suppliers and others, interior sustainability goals are easy to achieve.

Read More

Although PVC has numerous health and environmental concerns, it is still one of the most widely used plastics in the world. Performance and budget friendly options make it a preferred product for many installations, excluding healthcare. Due to the toxicity of vinyl in manufacturing, use, and end-of-life, alternatives have been sought out and are readily available. Silicone and Polyurethane for upholstery, TPO and Phthalate-Free vinyl for wallcovering, and recent phthalate-free options for flooring are available from many vendors. They all provide the durability and cleanability vinyl proponents are looking for without the toxicity no one wants.

Read More

Valley Forge Fabrics focuses on ways to better enhance quality of life specifically in sustainable products and processes. The product development decisions taken on by the company combine the realities of hospitality budgets, strict code requirements, environmental and health concerns, and the consistent desire to create innovative and fabulous interiors that meet the expectations of a very varied and always changing audience. Valley Forge’s large size and the considerable industry it serves results in a substantial effect on design and innovation as well as sustainability.

The Association for Contract Textiles (ACT) has great advice for specifying coated fabrics for healthcare interiors. Performance and durability are always top of mind in selection. Understanding where a product will be placed along with expectations for longevity, help in selection for high-traffic healthcare settings. Knowing the cleaning protocol used by the facility, is crucial in making choices as well. Fabrics are cleaned, sanitized, and disinfected rigorously in this environment. Often, testing of cleaners is recommended. Healthcare interiors are serious about reducing material toxicity and may have specific ingredients they are trying to avoid. Certifications will help achieve these goals. Remembering to review selections with the furniture companies chosen, is necessary to check for compliance. Not all furniture styles work well with coated fabrics. By keeping these criteria in mind, designers can be sure their selections will work beautifully and stay beautiful as long as they are needed.

read more

Illinois bio-tech company LanzaTech has developed a new polyester from recycled carbon. The fiber has the same properties of virgin polyester but contains no petroleum. Instead, ethanol fuel is created using captured carbon emissions from waste gas and other sources, which are then turned into polyester fiber. At the end of use, the carbon-sourced polyester can be recycled back into ethanol and then back into polyester again, promoting circularity within textile production, using an abundant sustainable resource.

read more

Plastics are here to stay, as it takes centuries for nature to break them down. Designers are taking the lead on making change to plastic use without waiting for regulation to mandate it. The focus is on “Disruptive Materiality”, the concept of combining with biosciences to redesign the products we know using bio-based raw materials, rather than petroleum based sources. Instead of lasting centuries, products will be designed to return to nature after their useful life. There is an incredible amount of plastic debris that can be harnessed as building blocks for new materials while bio-plastics begin to find a place in the market. The idea of reduce/reuse/recycle is the beginning. Redesign is the future.

read more